Understanding The Nubbin Device: A Closer Look At Flange Sealing

Have you ever stopped to think about the intricate details that go into keeping things sealed in industrial settings? It's a pretty big deal, actually, especially when you're dealing with pipes and pressure. Getting a perfect seal is, you know, absolutely critical for safety and for things to work right. Sometimes, a tiny feature on a flange can make all the difference, and one such feature is what we call a nubbin device. This little element, though small, really plays a part in how well a connection holds up, so it's worth getting to know more about it.

This discussion about the nubbin device, it really highlights how specialized industrial design can be. We're talking about something that's just a small tooth, more or less, that's put onto a flange. It's not something you just stumble upon; it's very much a precise part of the manufacturing process. These little details are often, you know, specified by the folks who make the joints, which tells you how important they are for particular uses.

So, we're going to get into what this nubbin device is all about. We'll explore why it's there, when it might be used, and even when it's better to avoid it. We'll also touch on how it affects sealing performance and what designers think about when they're putting together a flanged joint. It's, like, a really specific topic, but it has big implications for anyone working with these kinds of systems.

Table of Contents

- What Exactly is a Nubbin Device?

- Nubbin Device and Sealing Efficiency

- Applications and Design Choices

- Code References and Design Guidance

- Personal Preferences in Design

What Exactly is a Nubbin Device?

Definition and Design

A nubbin device, when you get right down to it, is just a small tooth. It's, you know, a raised bit of material. This little feature is created through a machining process. You'll find it specifically on the joint contact area of a flange. It’s not just a random bump, but a very deliberate design element, actually. This small, raised section is shaped with precision. It sits right where the flange meets another surface, helping to form a seal. So, it's a very specific kind of detail that is put there on purpose.

It's, like, a rather narrow raised area. This area is found right on the face of the flange where the gasket sits. The code, you see, often calls this particular feature a nubbin. It's a term that's used within the industry to describe this specific design. This small elevation is quite distinct. It’s a part of the flange’s overall shape, really. This shaping, as mentioned, is done by machine. So, it’s a controlled and consistent feature on the flange surface, you know, for a reason.

Manufacturer Specifications

This whole idea of a nubbin device, it's a very detailed issue. It's not something left to chance, apparently. Joint manufacturers, the folks who make these components, they normally specify when and how to use it. They have their reasons, of course, for including or excluding such a feature. So, it’s part of their engineering guidance. You’ll often find it in their product documentation. This means it's a considered part of the design. It's not just an afterthought, you know, but a planned element.

The manufacturers, they put a lot of thought into these specifications. They consider the materials, the pressures, and what the joint needs to do. So, if a nubbin device is there, it's because the manufacturer believes it serves a purpose. It's, you know, a very particular detail. This level of specificity highlights the precision involved in industrial component design. It tells you that every little part has a role. And that role is, more or less, defined by the people who build these things.

Nubbin Device and Sealing Efficiency

Performance Insights

Now, here's something interesting about the nubbin device and how well things seal. There was, you know, a conclusion reached regarding this. It was found that flanges without a nubbin actually sealed better. This might seem a bit counterintuitive to some people, but that was the finding. The absence of this small tooth, it seemed to improve the sealing action. So, in some respects, less can be more here. It's a pretty important point for designers to consider, really.

This insight is, like, a key piece of information for anyone designing or maintaining these systems. It suggests that while the nubbin device has its uses, it might not always be the best choice for achieving the tightest seal. The performance difference was clear enough to draw a specific conclusion. It points to the idea that simpler designs can, sometimes, be more effective. This is, you know, a practical lesson learned from actual observation.

Cost Considerations

Given that flanges without a nubbin device sealed better, there's another angle to consider: the cost. The conclusion was that the cost of machining off the nubbin is justified. Why? Because it leads to an increase in sealing efficiency. So, even though there's an extra step involved, the benefit outweighs the expense. This is, you know, a pretty clear business case.

It means that spending a little more upfront to remove this feature can save money down the line. A better seal means fewer leaks, less product loss, and maybe even less downtime. So, it's a very practical decision, you know, based on performance and economics. The initial cost of machining is, more or less, an investment. And that investment pays off in improved operational reliability. This is a good example of how engineering decisions are often tied to financial outcomes, too.

Applications and Design Choices

Ultra Vacuum and High Pressure

When you think about where a nubbin device might come into play, very specific environments come to mind. Based on what was read, it's relevant for ultra vacuum applications. In these settings, you need an incredibly tight seal. Any tiny leak can, you know, completely ruin the vacuum. So, the design of the flange and gasket is absolutely critical here. It's a very demanding environment for sealing components, really.

Beyond ultra vacuum, consider high-pressure situations. For example, there was a task to design a flanged joint for fluorine gas at 1000 psi. That's a lot of pressure, obviously. For such demanding conditions, every design choice matters immensely. You need a seal that can withstand that kind of force without giving way. So, the choice of gasket and flange facing, including whether to use a nubbin device, becomes a very serious consideration. It's about safety and reliability, you know, at the end of the day.

Gasket Compatibility

The type of gasket used is a huge part of this whole picture. It's like, a very important pairing. TEMA, for example, allows the use of any desired facing. This includes the described nubbin. So, designers have flexibility there. But, you know, personal preference also comes into play. One person mentioned generally avoiding nubbins, except when working with flat metal gaskets. This suggests a specific compatibility. It's a nuanced choice, apparently, depending on the gasket material.

When you're dealing with flat solid metal gaskets, the nubbin device can actually be quite useful. It’s often used with these types of gaskets, you see. The reason is to reduce the seating load. This also means less bolting is needed. So, for certain gasket types, it makes the assembly process a bit easier. This is, you know, a very practical benefit. It shows that the nubbin isn't universally good or bad; its value really depends on the specific gasket it's paired with. It’s all about finding the right combination, really.

Real-World Scenarios

Let's look at some real-life examples, because that helps to put things in perspective. Imagine two existing girth flanges that are being mated together. In one instance, one of these flanges has a nubbin. This nubbin is 1/64” high and 1/8” wide. The gasket between them is djaf iron, which is 1/2” wide. This is a very specific setup, you know, that engineers encounter regularly. It’s not just theoretical; it’s what’s out there.

Another scenario involved putting together a calibration stand. Here, a pump has a 3-inch, 150-pound steel flat-faced flange for its suction side. Then, there's a steel raised face flange and gasket to mate to it. These are common components in industrial systems. The decision of whether a nubbin device is present or needed on either flange is, you know, a practical design consideration. These everyday situations highlight the importance of understanding these details. It's about making sure everything fits and seals correctly, basically.

Code References and Design Guidance

ASME Standards

When it comes to designing flanged joints, engineers often turn to established standards. One such standard that was looked at is ASME B16.5. This code provides guidance for piping flanges and flanged fittings. So, it's a very important reference, actually. Thinking about a class 600 raised face design, for example, would involve checking these specific guidelines. These standards, you know, ensure consistency and safety across the industry.

The code itself defines what a nubbin is. It calls it a narrow raised area on the flange gasket seating face. This definition is, like, pretty clear. It helps everyone in the field understand what they're talking about. Following these codes is, you know, absolutely essential for proper design. They provide the framework for how these components should be built and used. So, if you're designing a joint, you'll probably be looking at these sketches and specifications, too.

Reducing Seating Load

One of the key reasons a nubbin device is used, as the code points out, is to reduce the seating load. This is, you know, a significant benefit. When you have a solid metal gasket, you need a certain amount of force to get it to seal. A nubbin can help achieve that seal with less force. This also means that less bolting is required. So, you don't need to tighten the bolts as much. This can make assembly easier, and it might even reduce stress on the bolts themselves.

This reduction in seating load is a very practical advantage. It means the joint can be put together with less effort. It also means the components might last longer, you know, because they're not under as much strain. This particular application of the nubbin device is, you know, quite common with flat solid metal gaskets. It’s a clever way to optimize the joint design. So, it's not just about the seal itself, but also about the forces involved in creating that seal, too.

Personal Preferences in Design

It's interesting how personal preferences can play a part in engineering design, even with established codes. One person mentioned generally avoiding nubbin devices. This was true, you know, except when using flat metal gaskets. This isn't necessarily a rule, but rather a way of working that someone has found effective over time. It shows that while standards exist, individual experience and judgment also guide choices. So, it's a bit of a blend, really.

This personal approach, like avoiding them unless with flat metal gaskets, highlights the nuances in design. It suggests that while the code allows for certain facings, including the nubbin, engineers might develop their own best practices. This kind of practical wisdom comes from, you know, years of working with these components. It's about finding what works reliably for you. So, it's not just about what's allowed, but what's preferred based on real-world outcomes, too.

When looking at design sketches, for example, it was noted that sketch 2.5.2 is just for determining effective gasket width. If using a nubbin, you'd more likely follow sketch 1(a) or sketch (2). But then, you know, the person added, "I wouldn't." This kind of direct, personal advice is quite telling. It suggests that even when a design is technically permissible by code, practical experience might lead to a different choice. It's a very human element in a very technical field, actually. It shows that engineers make judgment calls, too.

Frequently Asked Questions About the Nubbin Device

What exactly is a nubbin device on a flange?

A nubbin device is, you know, basically a small, raised tooth or a narrow, raised area. It’s created by machining on the joint contact area of a flange. It's a very specific design feature. This little elevation sits right where the gasket would go. So, it's part of the flange's prepared surface. It’s not just a random imperfection, but a deliberate part of the design, actually.

Does a nubbin device improve sealing performance?

Based on observations, flanges without a nubbin device actually sealed better. The conclusion was that removing the nubbin, despite the machining cost, was justified by an increase in sealing efficiency. However, it's often used with flat solid metal gaskets. This is, you know, to reduce the seating load and the required bolting. So, its benefit really depends on the specific gasket type and application.

When might a nubbin device be used in flange design?

A nubbin device can be used in various applications, particularly those requiring specific sealing characteristics. It's been referenced in discussions around ultra vacuum systems. It's also, you know, often considered when designing joints that use flat solid metal gaskets. This is where it helps reduce the necessary force for sealing. So, it's not for every situation, but it has its place in certain specialized designs.

To learn more about flange design principles on our site, you can explore our various articles. You might also find this page helpful for understanding gasket materials. For deeper insights into industry standards, you could also check out resources like the American Society of Mechanical Engineers (ASME), as their codes are often referenced in these discussions.

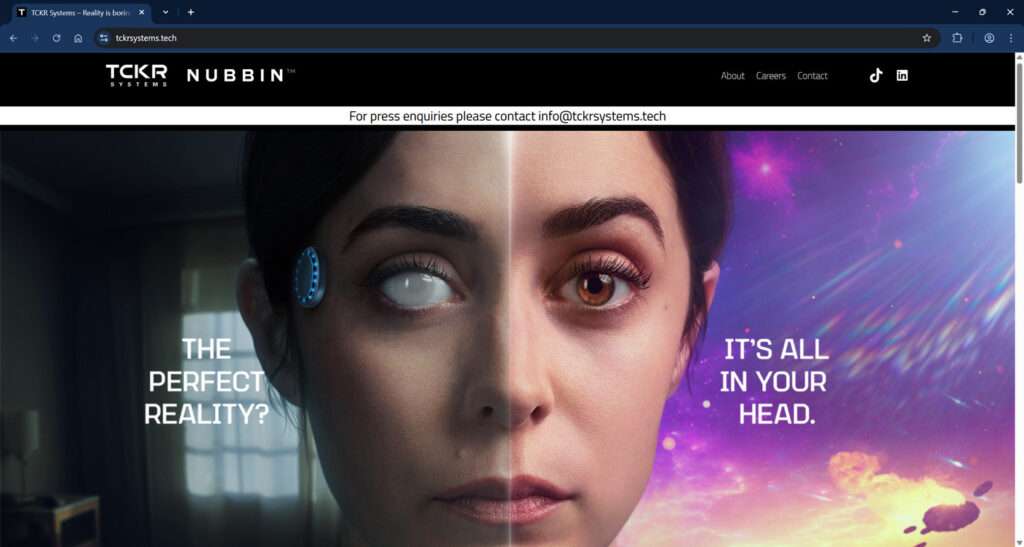

Nubbin by TCKR Explained: The Tiny Brain Device That’s Blowing Up the

What is the Nubbin device? Black Mirror Season 7 Tech explained - Zero

Nubbin Device Explained: Is It Real Or Just Black Mirror’s Viral Hoax?